a few Laws Of TBPS 454

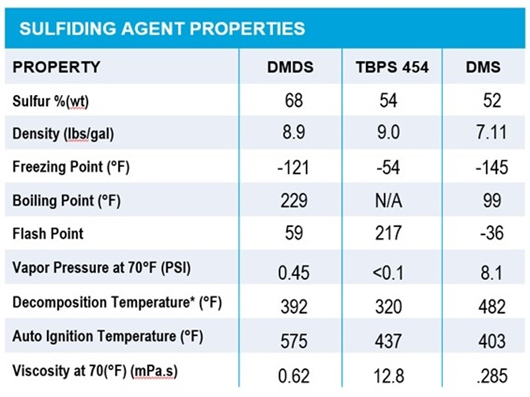

We sell as well. 68937-96-2) MSDS, density, melting point, boiling point, structure, formula, molecular weight etc. Content articles of di-tert-butyl polysulfide are included mainly because well. Hangzhou DayangChem Co. Ltd will be a comprehensive enterprise which specializes inside development, production and trade of pharmaceutical drug, agrochemical and dyestuff intermediates as well as some special type of dental appliance reagents. Produced by ChevronPhillips Chemical Company underneath the trade title “TBPS 454”, TBPS offers some advantages over other sulfiding compounds, although a number of factors should end up being considered before selecting it as the sulfiding agent. In contrast to other sulfiding brokers, TBPS 454 is usually not classified because a flammable substance. TBPS 454 is actually a sulfiding agent which is often used, along with a reducing agent such as hydrogen, to remodel metal oxide types to a material sulfide crystalline period in situ with regard to hydrotreating catalysts. The particular sulfide (1), disulfide (2), and trisulfide (3) were unable to suppress typically the rate of autoxidation. The rationale is usually straightforward; ongoing from the trisulfide to be able to tetrasulfide (and higher), the S-S bond strength weakens substantially (53. 4 to be able to 36. 3 kcal mol−1, respectively), 21 such that that approaches the RS(O)-SSR bond strength (29. 8 kcal mol−1). 20 Moreover, we wondered how this specific reactivity would translate from the biologically-relevant temps where we have got studied the responses of the stimulated thiosulfinates and trisulfide-1-oxides to more industrially-relevant (elevated) temperatures.

As i have said in the Launch, the central S-S bond in the tetrasulfide is seventeen kcal mol−1 weaker than the S-S bond in a trisulfide due to the greater stableness of perthiyl foncier over thiyl foncier. The persistence of perthiyl radicals also underlies the better reactivity of polysulfides at elevated temperatures in accordance with their 1-oxides, since homolytic S-S bond cleavage will be reversible in the former, however, not inside the latter. All of us previously reported that will trisulfides, upon oxidation to their related 1-oxides, are remarkably effective radical-trapping anti-oxidants (RTAs) at normal temperatures. Herein, we all show that the homolytic substitution mechanism responsible also functions for tetrasulfides, yet not trisulfides, disulfides or sulfides. Homolytic substitution of the peroxyl radical about a tetrasulfide produces a peroxyl-perthiyl adduct. Experimental and computational investigations suggested the reaction proceeds via a concerted bimolecular homolytic substitution by typically the peroxyl radical from the oxidized sulfur center, liberating a new highly-stabilized perthiyl major.

The reactivity will be unique to larger polysulfides (n ≥ 4), since homolytic substitution upon all of them at S2 produces stabilized perthiyl radicals. We certainly have since asked yourself if higher polysulfides can be amenable to be able to direct substitution by peroxyl radicals. They proposed that the sulfoxide undergoes a Cope-type elimination in order to yield a sulfenic acid (Scheme 2A), which they surmised would undergo fast reactions with peroxyl radicals. The increased polysulfide-1-oxides are, enjoy the tetrasulfide, turned on to substitution by simply peroxyl radicals. However, for the same reason they usually are activated to replacement (weak S1-S2 bonds), the higher polysulfide 1-oxides decompose readily. At the same time, since the decomposition products are usually small molecular hydrocarbons, the catalyst may not be contaminated by carbon deposition. With this test, a sample of the lubricant was placed in the heated gear circumstance containing two spur gears, a test keeping, and a copper catalyst. Features: high sulfur content, large purity of natural polysulfides, no harmful particles, no metal ions, no catalyst poisoning when used being a pre-vulcanizing agent; large molecular weight submission, wide decomposition temp range during vulcanization, and catalyst concentration can be avoided when vulcanizing the particular catalyst Exothermic, does not sinter the catalyst, and facilitates the sulfidation procedure. Preferably, the organic polysulfide will include at least forty five wt % plus, more preferably in least 50 wt %, and many ideally at least 55 wt % in the dialkyl polysulfide chemical substance or mixture associated with dialkyl polysulfide compounds.

Pat. No. 4, 575, 431), five. 8 wt per-cent (28. 9 grams) of thiadiazole (available as Hitec® 4313 from Ethyl Corporation), and 4. 81 wt % (24. 0 grams) of solvent refined 100 neutral base olive oil (Exxon 100N) had been mixed until the mixture was homogenous. 3. 8 wt % (456. zero grams) of the gear oil additive formula described above, 12. 2 wt percent (1, 464. zero grams) of solvent refined bright inventory base oil (Citgo 150), and 84. 0 wt per-cent (10, 080. 0 grams) of hydro-processed 600 neutral bottom oil (Chevron 600N) were mixed from 130° F. till the mixture had been homogenous. Among other factors, the present innovation is based on the amazing discovery that a new gear oil ingredient composition and gear oil composition having lower odor and low chlorine significantly reduces corrosion of orange metal components of axle assemblies and transmissions, especially copper and copper mineral alloys. The sulfur components in conjunction with phosphorus components produce a formula that degrades typically the copper. Combinations of such categories of sulfur-containing antiwear and/or extreme pressure agents might also be utilized, such as a mix of sulfurized isobutylene and di-tert-butyl trisulfide, a variety of sulfurized isobutylene and dinonyl trisulfide, a combination of sulfurized tall essential oil and dibenzyl polysulfide. Would the polysulfides and/or their 1-oxides be too labile to be successful in this ability?